This post will describe the different aspects of the Indian tune. It is a short guide to the tables that we have access to and the main tables we will change for tuning.

Open the C3 module in the Power Core Software Suite's Application Launcher windows. Once it is opened, select the folder icon to open a tune. In this case, we are going to open your STK file. The following is the window you should get. (Note, I have reduced screen clutter by configuring my desktop not to have the gauges that are displayed on the right-hand side of the C3 module).

C3 Module with an Opened STK file

(Click on image to expand)

What you see is the essences of a tune. The tree on the left-hand side are a visible organization of the tables we will use to modify our tune, it is called Explorer. Think of it as the Tune Explorer as Windows has the File Explorer. The top left-hand window is the current tune(s) we have opened and can perform task on.

Selecting the Tune Info will bring up the following dialog. This box helps you keep track of what you have done to the tune. It is a good place to put what corrections you are making as well as any other tables that might be changed while you are tuning.

Tune Info

(Click on image to expand)

The dialog box has two other tabs...Tune Security and Advance. The Tune Security tab allows you to assign a password to the tune as well as to lock it to any PV3 or PVCX GUID, with is an unique identifier for that device. I suggest not to set that box, but certainly go ahead and assign a password if you wish. Any tuning you do on your bike is specific to your bike and is your intellectual property. Just remember that if you forget the password, then you are out of luck, there is no recovery for that situation.

The Advance tab will display the information on the STK file and other related information. This screen is one that you usually never touch

The next item down the Tune Explorer list is the Monitor folder. Selecting this shows the following:

Monitor

(Click on image to expand)

These are items to you view or monitor while connected to the bike and you are bringing data into Power Core Software Suite directly. For our purposes, we will be ignoring this table.

This next table is very important but one of the least understood. The Mass Flow Through the Throttle Body is the only table in the Air Flow folder.

Mass Flow Through the Throttle Body

(Click on image to expand)

This table is very important for startups, for transitions between MAP stable points and most importantly if the MAP sensor fails. In tuning talk, this is the Alpha-N table. It strictly deals with the Throttle percent opening, the engine RPM, and what you think the air flow is through the throttle body. Our engines do not have a Mass Air Flow sensor, so we have to tell the ECU what this value is at each cell point. Most tuners I know either ignore this table or hit certain cells to fix a problem (like cold starting stability). I have built an equation that deals with this table, but we will only deal with this table after we first gain a through understanding of tuning.

The Drive By Wire tables are in the Drive By Wire folder. For 2014 through 2018 Indian bikes, this is a very easy, straightforward set of curves. With the introduction of the Drive Modes introduced in the 2019 TS111 & TS116 models as well as the FTR-1200 models it became a lot more complicated (to keep track of). The same principals apply to those models as we will discuss and show here, there are just more to keep track of.

Drive By Wire (DBW)

(Click on image to expand)

Under the folder labels Fuel are a lot of tables. The Component Protect tables I am not going to go through. These are set by Polaris and only under very rare conditions would you need to change them. Also, the EGT values are calculation value(s) from Modeled EGT table and not measured. You have to take that at face value.

The tables we will be extensively correcting are in the Individual Cylinder. The Start Up Fuel and the Main Target AFR we set to obtain the operation parameters we want during and after tuning. The Delay for fuel cut-off (Gear Change) is a useful value to help eliminate exhaust decal popping. The rest of the tables I leave alone the majority of the time and I have no plans to discuss.

Fuel

(Click on image to expand)

Individual Cylinder

(Click on image to expand)

There are four tables under the individual cylinder folder. These tables balance the fuel between front and rear cylinder and are vital to a smooth running well balanced engine. Injector Compensation Factor Front and Rear tables make very minor changes, which I now usually do not correct. They main tables for fuel balance are the IPW Comp tables Front and Rear. These are the tables where we will spend the most time on.

Main Target AFR

(Click on image to expand)

This table dictates the desired AFR (Air Fuel Ratio) that we want the engine to operate at under various loads and RPM. This table is mis-understood by most beginning tuners. The values you enter into this table mean nothing except for 14.7. When you put the value of 14.7 into any cell, if operating in that cell (load and RPM match), then the ECU will operating in Closed-loop operation using the narrowband O2 sensors to maintain 14.7:1 exhaust AFR. Another value in these cells and the ECU will attempt to meet that target AFR by performing calculations base on the many other tables that we will be tuning. It is not a supervised AFR target like the 14.7 is. So, you can really mess up the engine by going very lean by entering a value other than 14.7 if your fuel tables have not been properly corrected. We will be discussing this further in future posts or through discussions on the Indian Motorcycles Net Forum.

The next folder deals with the Fuel Injector. The tables we are interested in are the Injector Latency and Injector Scaling. These table look like this:

Injector Latency

(Click on image to expand)

This table impacts starting and running under various battery voltage conditions. I usually use the injector specs from performance supplies that have tested this. If you are having trouble starting, changing the values in the lower voltage cells usually helps.

Injector Scaling

(Click on image to expand)

Injector scaling is very important if you change injectors to a different size. This is a very easy value to calculate and is a ratio. The three common sizes of injectors for our motorcycles is 280cc, 350cc, and 450cc. The 280cc injector has been used on the 2014 through 2019 TS111 & TS116 bikes, Scouts and FTR's. The 2020 and up move to 450cc injectors on the TS116 stage 2 kit.

The injection end angle table is a pretty intimidating table and should be left alone unless you are converting a tune from one checksum over to another or you are on a Dyno and throughly understand what this table does.

Injection End Angle

(Click on image to expand)

I do not plan to go through this table, if you have to touch this table, the Indian Motorcycle Net forum would be the best place for that discussion. The rest of the table under the Fuel Injector should be left alone.

The next folder in the Tune Explorer tree is the Idle folder. In the 2014 through 2018 models, it has three tables. The 2019 and up TS111 & TS116 models and the FTR-1200 has more due to the extra drive modes available.

We will basically be touching two of the three tables, the Idle Speed and the Idle Speed 3d tables.

Idle Speed

(Click on image to expand)

Idle Speed 3d

(Click on image to expand)

The Idle Speed 3d table is a very important table to adjust the idle drop when downshifting and slowing down. This was the source of a lot of behavioral issues in the first couple of years of Indians.

The next folder in the tree is the Knock Control. I will not be going into an in-depth discussion with these tables, but will provide my guidelines on the one table I view beneficial in tuning. That is the Max Knock Retard table.

Max Knock Retard

(Click on image to expand)

The next folder is the Miscellaneous. This folder has the Engine Displacement table. It is important to set your Engine Displacement correctly. You can use this table to vary the overall tune up or down if you find you need a global correction. Do not knock yourself out if it does not exactly equal your displacement. I use it in a ratio way when I have to build a tune for a 118", 120", or 126". Most of the time, you will not touch this value.

Engine Displacement

(Click on image to expand)

The next folder deals with speed and rev limits. This is one area you have to be careful, yet should modify. I will be providing my recommendations for these tables. The tables of interest are: Rev Limit 1, Rev Limit by Gear, Rev Limit hysteresis, and the Speed limit per gear. In newer models, these individual tables have been replaced by a single table array. Makes changes easier.

Rev Limit 1(Click on image to expand)

Just because we can raise the rev limit, does not mean it is a good idea. Depending on the cam you are running, you will run out of power band way before the limit is reached. Also, you must factor in the risk of engine damage due to over rev and design spec of rod and crank.

Rev Limit by Gear

(Click on image to expand)

This table sets the rev limit by gear. I usually set this entire table to the Rev Limit 1 value.

Rev Limit Hysteresis

(Click on image to expand)

This is the bandwidth of where the rev limit kicks in and out. I usually tighten this number.

Speed Limit per Gear

(Click on image to expand)

Just like the rev limit, just because you can set it up, should you and can the bike actually reach that speed? Our bikes are basically limited per RPM ratios to 124 MPH iirc. I have a spreadsheet that I built a while back that calculates the different speeds available depending on tire size, gear, and RPM of engine. It is what it is. Also, HP comes into play. It takes a lot of power to push our bikes through the air and frankly, a stock or stage 2 TS111 is not going to exceed the overall speed limit of the gear/engine RPM train.

On newer calibration, the six tables have been combined into an array as shown below.

Speed Limit per Gear

(Click on image to expand)

You should never ever set this table above the rating of your tires. I usually set it at 130 mph, which most bikes will never achieve unless on a Dyno.

Our next folder down the tree is Sensors. Most calibrations contain the MAP folder. The various settings include the sampling window, offset, slope, and min/max voltage. We will not be touching these values except when we go to tune the Mass Flow through the Throttle Body table and we need to fail the MAP sensor.

Map Sensor Tables

(Click on image to expand)

The next folder down the tree is the Spark folder. This folder contains the tables associated with the timing of the engine. Polaris has chosen a very complicated method of timing. It is the source of a lot of issues in engine performance when transitioning from idle to run. I will get more in-depth on this subject as we start the tuning process.

Spark Folder

(Click on image to expand)

You can destroy an engine fairly quickly with bad timing settings. Luckily we have Knock Control that provides some safe guard against this, though it is not fool proof.

The spark folder contains the Coil folder. This folder has the dwell table for the coil. You can make modifications to this table, but need to be careful or you could destroy your coil due to heat. Some folks on the forum advocate a certain setting which we will explore when we get to this subject on tuning.

Coil Dwell

(Click on image to expand)

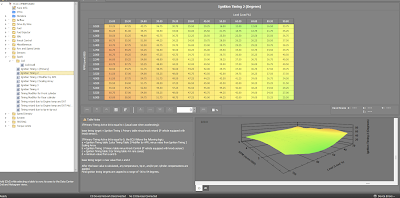

The next tables on the list are the timing tables. The first and most important is the Ignition Timing 1(Primary) table. This table comes into play almost all the time and is the one we are most interested in.

Ignition Timing 1 (Primary)

(Click on image to expand)

If you look at the notes for this table you will see how complicated this is:

If Primary Timing Active bit is equal to 1 (usual case when accelerating):

base timing target = Ignition Timing 1 Primary table minus knock retard (If vehicle equipped with knock sensor).

If Primary Timing Active bit is equal to 0, the ECU follows the following logic:

a = Ignition Timing table 2 plus Timing Table 2 Modifier by AFR, minus value from Ignition Timing 2 Scaling Array

b = Ignition Timing 1 Primary table minus Knock Control (If vehicle equipped with knock sensor).

c = Ignition Timing table 3 (or timing table 4 in rear cases)

d = minimum value from a and b

Base timing target = max value from c and d

After the base value is calculated, any temperature, tip-in, and/or per cylinder compensations are applied.

Final ignition timing targets are capped to a range of -36 to 54 degrees.

Quoting a very smart ECU engineer at Dynojet: "In general, primary timing is active when idle control is not active and you are not in decel. However, if there are issues, limits exceeded, etc then the ECU will kick out of Primary timing. There is no set threshold of any sort, it’s a pretty complex algorithm. I would not question “why Primary Timing is active”, but rather “why is it not active” if you ever see it is not. If you’re not in decel or idle, something is probably off.

As for the other timing tables, timing 2 should really only be idle control.

Timing 3 is actually Minimum allowed timing for combustion and Timing 4 is Minimum allowed timing for heat. These tables are generally only active when in decel, but they are always checked to provide a floor for requested advance in the case of knock retard or other factors affecting base timing.”

So in summary, the timing should always be the Ignition Timing 1 (Primary) unless we are at idle or decel. You can view data bit in the log file titled "Primary Timing Active bit" to make sure the Ignition Timing 1 (Primary) table is active.

Ignition Timing 2 is used during idle, but it gets more complicated since it also relies on the Timing Table 2 Modifier by AFR and Ignition Timing 2 Scaling array!

Ignition Timing 2

(Click on image to expand)

This table has the same notes of the Ignition Timing 1 (Primary) table.

Ignition Timing 2 Modifier by AFR

(Click on image to expand)

There are some things we need to look out for with this table. I will discuss further as we get into tuning. The notes for this table are:

Ignition Timing 2 Modifier by AFR

This table is only applied when Ignition Timing 2 is active.

Requested AF can never by leaner than 14.7, so the last 2 cells should never be hit unless the axis is re-scaled.

Requested AFR can never also never be richer than 6.2, so the cells lower than this will default to 6.2 if changed from stock.

Ignition Timing 2 Scaling Array

(Click on image to expand)

This array has 200 cells. I have never had a good explanation as to what drives this array internally. The notes for this table are:

This table is only applied when Ignition Timing 2 is active. The value from this table is subtracted from the Ignition Timing 2 table value.

Ignition 2 Scaling Index can be monitored to know which axis point the ECU is using.

Ignition Timing 3

(Click on image to expand)

Minimum allowed timing for combustion during deceleration

Ignition Timing 4

(Click on image to expand)

Minimum allowed timing for heat during deceleration

The next tables deal with modifying the timing per front & rear cylinder. These can be used if knock is detected on one cylinder instead of both. On the TS116, Polaris sets these tables extensively. I am only going to show the front cylinder table as they are both the same.

Timing Modifier for Front Cylinder

(Click on image to expand)

The note for Front and Rear are:

Timing modifier for Front (or Rear) cylinder. Changes here will affect ignition timing for only the Front (or Rear) Cylinder.

Timing retard due to Engine temp and IAT

(Click on image to expand)

The notes for this table are:

Timing change due to Engine Temp and intake air temp.

Normally used to retard timing at high temp, some OEM strategies use this table to add timing at cold temps.

Positive values will add and negative values will remove timing (after the multiplier table is applied).

Timing retard due to Engine temp and IAT Multiplier

(Click on image to expand)

The notes for this table are:

This value is multiplied by the timing retard for high Engine Temp or intake air temp to get a final result for retard.

A value of 1 results in 100% of the value from the Engine Temp Retard table being applied.

A value of 0 results in NO retard being applied.

Timing retard due to tip-in tip-out

(Click on image to expand)

This table can help with sluggish throttle response. The notes for this table are:

Timing retard for knock prevention due to throttle tip-in/tip-out

The next folder down the tree is one of the most important, Speed Density folder. In this folder we find the Volumetric Efficiency and the Volumetric Efficiency change from air pulsation.

Volumetric Efficiency

(Click on image to expand)

This is the table, with the IPW Comp tables that my equation will be working on. In a speed density system, this is the most important table and provides the mode of the engine ability to move air through the engine at various loads and RPM. If you have this table modeled correctly, then the ECU can make accurate calculations to hit the Target AFR table value.

Volumetric Efficiency change from air pulsation

(Click on image to expand)

This is a useful table when converting tunes from one Tune CMP or Checksum to another. I usually do not modify otherwise.

The next folder down the tree is the System folder. In this folder you will find the Misfire Monitor folder. There are tables in this folder that when modify go a long way in preventing the spurious mis-fires that our Indians tend to throw.

Misfire Monitor

(Click on image to expand)

I usually set these tables to equal other Tune CMP calibrations that have more stable engine misfire detection. The last table, Time for Misfire Detection After Start is very useful to change to stop all the misfire codes during starting that we get on some bikes. I usually set this for 120 seconds.

Time for Misfire Detection After Start

(Click on image to expand)

The last folder down the tree is the Torque Limits. Depending on the Tune CMP, there will be a few to many tables. These tables will limit your torque output of the engine under certain conditions. It is easy to forget that our engine management system calculates the required torque demanded on the engine at any one time. I usually just max out the values or set them high so they don't come into play.

Torque Limit

(Click on image to expand)

Load Request Ceiling 01

(Click on image to expand)

This concludes our overview of the components in a tune. The next post will be setting up the method for tuning and recording our first set of logs to make fuel corrections.